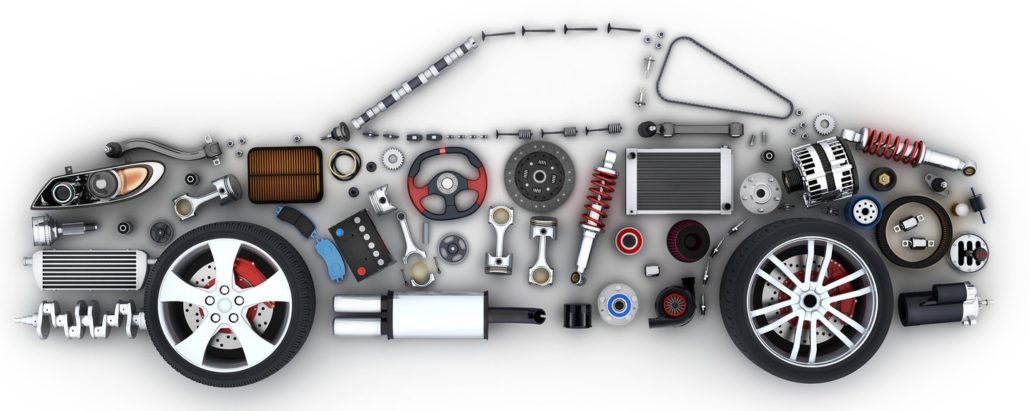

Original Equipment Manufacturer (OEM)

OEM — or original equipment manufacturer — is defined as a company that manufactures a product that is sold to another company, which resells the product under its own brand name. Business textbooks often refer to OEMs as “contract manufacturers.”

The term is flexible, but OEM usually refers to manufactured products in major industries. Yet it could also mean a company that makes the ingredients that go into a fast food milkshake, for example.

We at GLINTEKO’s sells the products on a business to business model.

Why the Need for OEM?

- They have the expertise needed to build the product, device or component that another company needs to build its product, primarily because they can mass produce the product on a regular and specialized basis.

- They can build a component, part or device more inexpensively than the company who buys the OEM product for their own products.

Yet there are additional reasons why companies like to partner up with OEMs. For instance, when a manufacturer or other business does business with an OEM, they receive a precision product component that meets their exact demands and conditions for production, delivery and management.

There are more reasons to align with an OEM...

Quick response times

With an OEM, you're dealing with a precision product component expert. They can turn around a request or a product delivery request in a short amount of time, given their experience and expertise in building a specific product component.

Quality component

When you ink a contract with an OEM, you're getting a production partner with years of experience in building specialty products and components. All parts built by an EOM are tested for quality and to ensure they match the partnering company's exact specifications.

Good customer service

A solid OEM partner knows that if they don't deliver the product and support a partnering company needs, they'll go elsewhere to get it. Consequently, an OEM doesn't only deliver quality products, it's expected to back that product up with robust technical and engineering support.

You get a warranty

Companies that partner up with an OEM should expect to get a manufacturer’s warranty. If there are any problems or product defects, the warranty protects the partnering company's investment. Adding value to your product, OEMs also provide a good return on investment to their business partners. Their parts, components and products extend the life of the partnering company's product, thus maintaining top performance and saving money with replacement parts, thus increasing the company's financial bottom line.

How Do OEM Work?

To best understand how OEMs work, you need to understand how OEMs and principal manufacturers work together.

Basically, OEMs and principal partners work under the following arrangement:

The OEM develops a product, part or component, and sells the product to a principal partner, who resells the product, usually directly to the public, under its own brand.

The principal partner does have some flexibility in dealing with OEMs. For example, a principal partner can structure a deal where it has an option to only work with selected products and under flexible terms.

Under that arrangement, the reseller can elect to purchase specific components, or can have the OEM manufacturer complete products for it to resell. These products come in plain boxes and aren’t for sale, by and large, in retail outlets.

That scenario is changing, though, as online retailers are beginning to market OEM products directly to end users for a discounted price. Auto enthusiasts rebuilding a new car or technology lovers who buy parts to build their own customized computer are good examples of end users who buy parts, often online, direct from retailers.

OEM and Economies of Scale

OEMs are attractive to principal partners because of their economies of scale.

That is, partners can benefit from OEM products and parts without having to dig deep and fund a new manufacturing facility and handle that production in-house.

Economies of scale mean the competitive leverage a larger company usually has over a smaller company. The bigger the business, the lower its costs of doing business. With OEMs, companies can benefit from the economies of scale of having a business partner take on the responsibility of building a product, component or part, instead of the partnering company. The OEM excels in building one product and only one product only, and thrives by building hundreds of thousands, or even millions of those products on a cost-effective, streamlined basis, and selling them to VAR’s and principal partners.

The purchasing partners benefit from an OEM’s economy of scale, as both pricing and manufacturing times are reduced by buying from an OEM partner. Those indirect cost savings are a big incentive for companies to do business with OEMs

GET STARTED WITH GLINTEKO TODAY!

At GLINTEKO, our unique expertise in strategy and technology helps companies reorient their focus, align stakeholders across departments, and leverage technology to gain a competitive advantage.

Let’s discuss small moves that can make a big impact on your business.